Mail Us: [email protected]

Call For Us: +86-13929487727

At Yuanji Company, we use advanced equipment to provide you with a variety of CNC processing services, including milling, turning, electrical discharge machining, wire cutting, surface grinding, thread processing, and so on. Using imported high-precision 3, 4, and 5-axis CNC machining centers, our professional mechanical engineers can process various plastic and metal materials to make turning and milling parts.

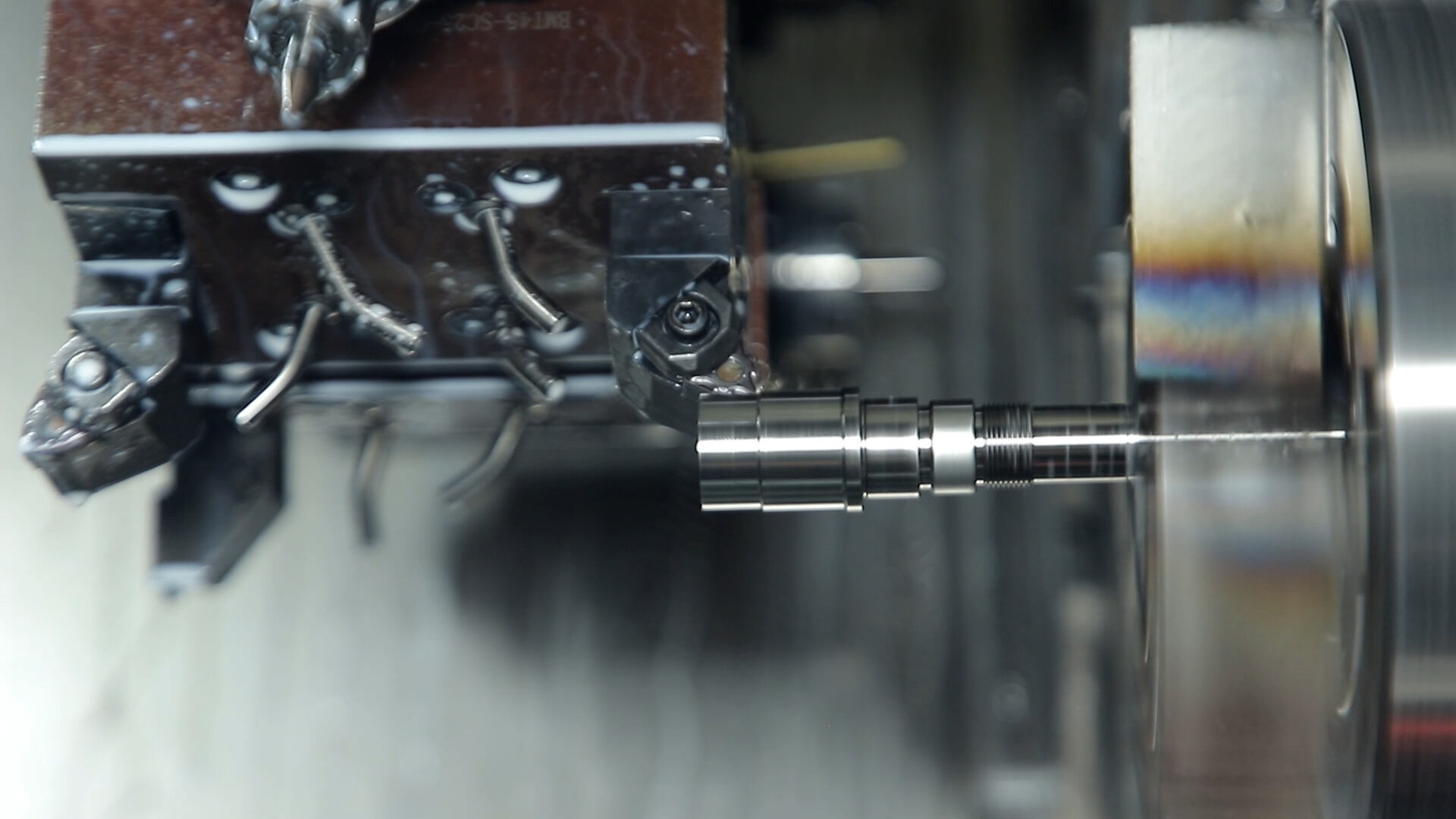

A CNC lathe is an automated lathe controlled by computer digital signals. Its core idea is: to write all the steps of processing parts (such as turning routes, process parameters, tool movement trajectories, etc.) into programs in the prescribed code format (referred to as G-codes), and then input them into the numerical control system. The numerical control system controls the servo motor of the machine tool through the servo driver, enabling the cutting tool to precisely perform cutting operations on the rotating workpiece along the preset trajectory.

In simple terms, it is an "automated lathe that can think for itself". The operator only needs to write or call the program, and it can automatically, precisely and efficiently complete the processing tasks.

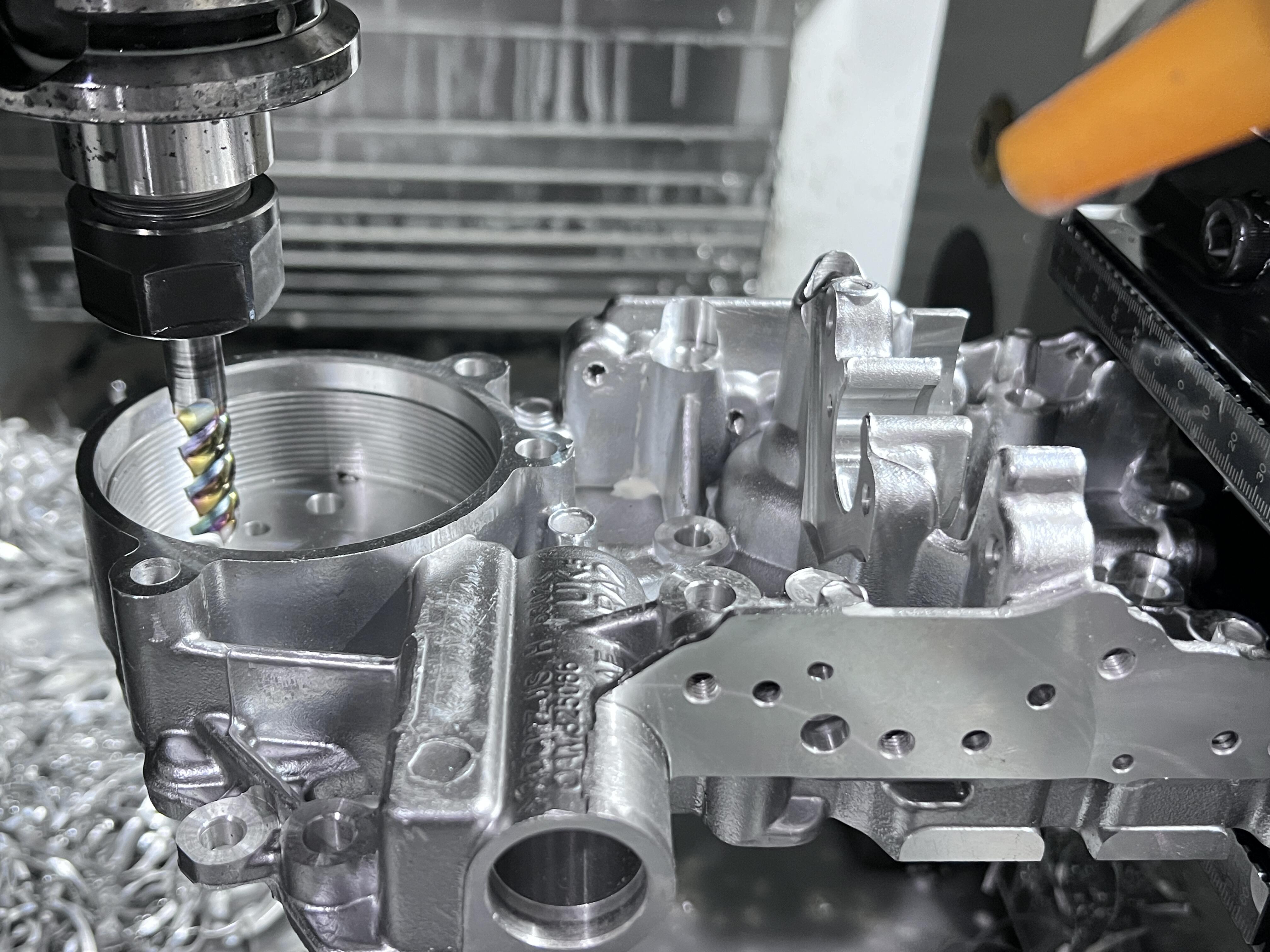

A CNC milling machine is a multi-functional and high-precision machine tool controlled by a computer. Its core feature is that the spindle drives the tool to rotate, while the workpiece is fixed on the worktable. Through the feed motion of the worktable in multiple directions, the rotating tool performs cutting operations on the stationary workpiece.

In simple terms, its working mode is like "a rotating engraving knife precisely carving on a fixed material", capable of completing a variety of complex processes such as milling planes, milling grooves, milling contours, drilling, and tapping.

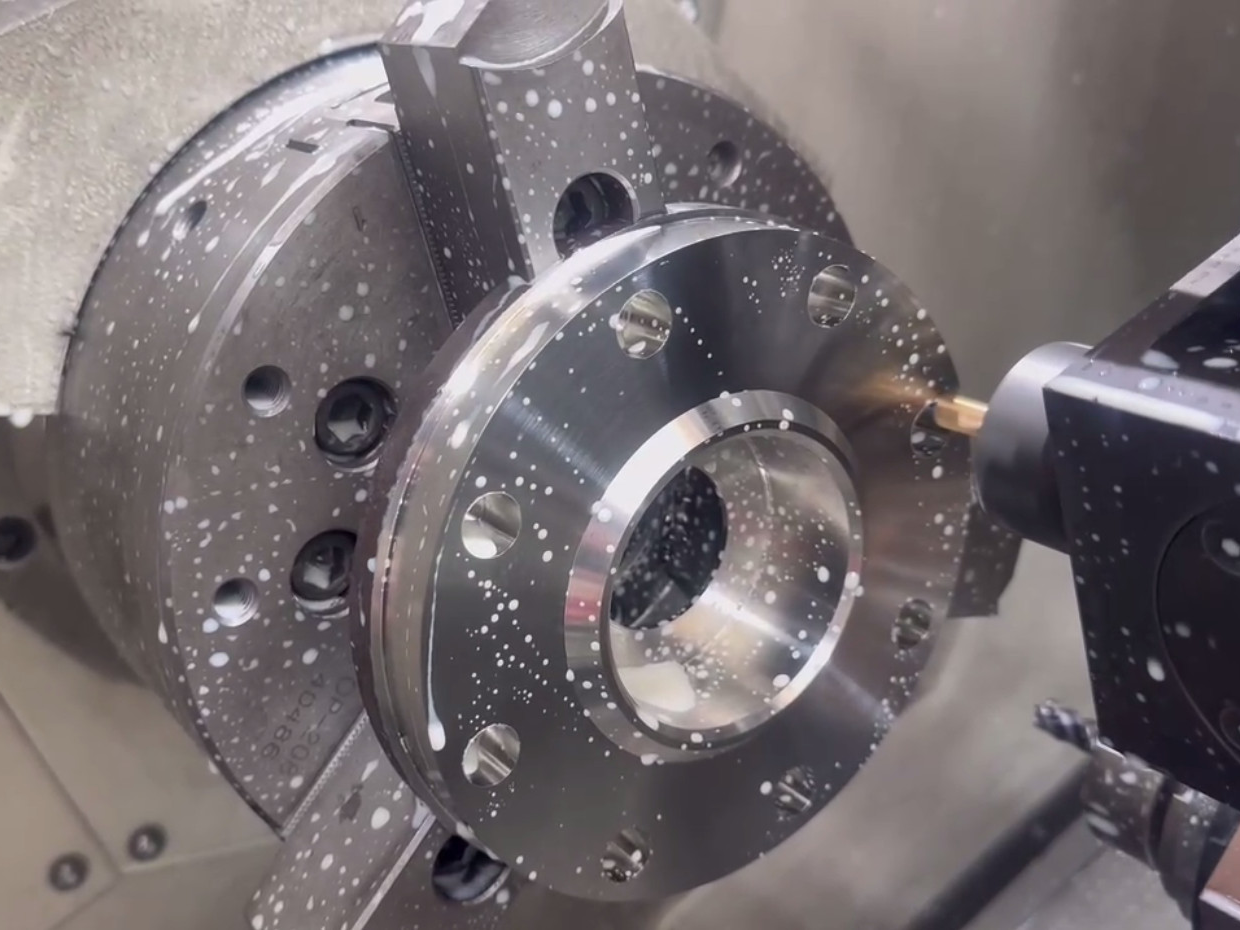

The CNC turning and milling compound machining Center (Turn-Mill Center) is a multi-functional and high-precision advanced manufacturing equipment that integrates the functions of a CNC lathe and a CNC milling machine/machining center.

Its core concept is: "One clamping, all done." The workpiece only needs to be clamped once, and the machine tool can automatically complete multiple processes such as turning, milling, drilling, boring, tapping, gear hobbing and even laser processing.

| CNC Lathe/Turning | CNC Milling | CNC Turning and Milling Compound | |

| Main Motion Axis | 2 axes: X (radial), Z (axial) | At least three axes: X, Y, Z (linear axis) | Multi-axis: X, Z, C (main shaft indexing), often with Y-axis, B-axis is optional |

| Core Feature | Power cutting tools, C-axis function, dual spindles | Automatic tool changer system (ATC), tool magazine | Power cutting tools, C-axis function, dual spindles |

| Main Processing Objects | Rotating body parts(Shaft, disc, sleeve, thread) | Non-rotating parts(Plates, boxes, molds, special-shaped parts) | Complex and multi-process composite parts(Eccentric parts, special-shaped parts, and parts requiring multi-sided processing) |

| Typical Processing Procedures | Outer circle, inner hole, end face, groove, thread | Milling planes, milling contours, milling cavities, drilling, tapping, boring | Turning + milling + drilling + tapping +...(Complete all in one clamping) |

| Metaphor | Specialist(Rotating parts processing expert) | Generalist(Versatile in shape processing) | All-powerful Superman(One clamping solves all problems) |

Our CNC processes are applicable to various materials, including mechanical-grade metals and plastics. Whether you need precisely machined aluminum parts or other materials, we can produce accurate rapid prototypes and small-batch production runs to meet your requirements. The following are some common materials:

| Material Series | Surface Treatment | |

| Aluminum | AL2011, AL2024, AL5052, AL6061, AL6063, AL6082, AL7075 | Sandblast, Color Anodized, Chemical Film, Brush, Polishing, Chrome Plated, Powder Coated, Laser Logo, Screen Printing |

| Steel Alloy | Q235, 1018, SPCC, A3, #45, SCM435, 40Cr, 4140, S2, D2, Cr2, Y13, Y15, 1.4301, 1.0570, 20MnB, 420C, 65Mn, 1020 | Zinc Plated, Black Oxide, Nickel Plated, Chrome Plated, Carburized, Heat treatment, Powder Coated, Painting, Mirror Polish, Carbon Pattern |

| Stainless Steel | SS301, SS303, SS304, SS316, SS316L, 17-4PH, 430, 440C, 420, 421, 321 | Polishing, Passivated, Blasting, Laser Engrave, Electrophoresis Black, Chrome Plated, Chrome Plated, Electrolytic Polishing, QPQ Black |

| Copper/Brass/Titanium | Brass H59, C1100, C3600, C2800, Red Copper, C93200 | Nickel Plated, Chrome Plated, Electrophoresis Black, Brush, Lacquer, Tin Plated |

| Plastic | ABS, PP, PC, POM, PEEK | Polishing |

Our factory has always been dedicated to product development services and manufacturing production. Whether you only have concept sketches or need structural optimization, our team of engineers can work closely with you to provide services such as DFM (Manufacturability Analysis), 3D modeling, and drawing optimization, ensuring that your design is both innovative and manufacturable, saving you precious time and costs.

Zero-risk prototyping: We break the minimum order quantity barrier of traditional manufacturing and support single-piece prototypes or small-batch production. You can try and make mistakes at zero cost, verify designs, test functions, and showcase ideas at the lowest cost, without fearing inventory pressure, making product iterations more agile.

Copyright © Dongguan Yuanji Technology Co., Ltd. All Rights Reserved - Privacy Policy