Mail Us: [email protected]

Call For Us: +86-13929487727

Casting is a forming process in which molten metal is poured into a pre-made cavity of a mold, and after it cools and solidifies, metal parts or blanks with certain shapes, sizes and properties are obtained.

The core principle is to utilize the fluidity of metals to achieve near-net forming of complex-structured parts. Casting is one of the most fundamental and widely used metal thermal working methods in manufacturing and is known as the "industrial cornerstone". Common products include engine blocks, gears, water pipe joints, artworks, etc.

Description: Sand casting is the most traditional and widely used casting method. It uses molding sand (usually silica sand mixed with clay or other binders) to make molds. A mold is usually composed of two halves (the upper and lower molds) and a core that may form an inner cavity. Molten metal is poured into the cavity of the sand mold. After solidification, the sand mold is broken to remove the casting. Sand molds are usually for single use.

Features: It has extremely wide adaptability and can cast parts of almost any size, any complexity and any alloy. The cost of molds (wooden molds or metal molds) is relatively low. However, the dimensional accuracy and surface finish of the castings are relatively poor, the allowance for subsequent processing is large, and the production efficiency is relatively low.

Main applications: Engine blocks, machine tool beds, large valves, water pump casings, sculpture artworks, etc.

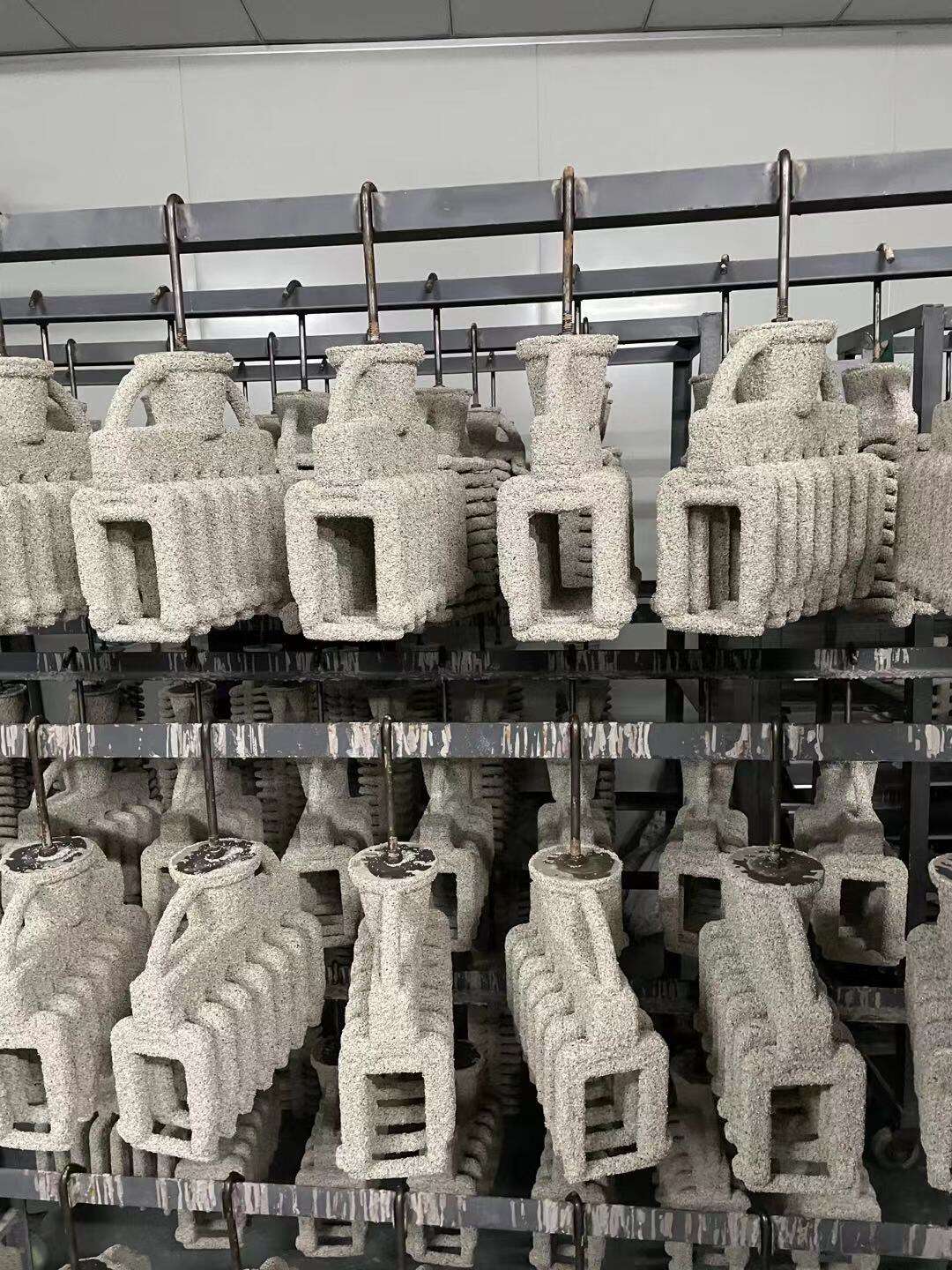

Description: Precision casting, usually specifically referring to investment casting, is also known as "lost-wax method". The process is as follows: First, a precise fusible model is made with a fusible material (such as wax). Then, a specially formulated refractory coating is repeatedly applied to the model and sprinkled with sand grains. After hardening and drying, an integral shell is formed. Next, the model is melted and discharged with hot water or steam. Finally, the shell is fired at high temperature and molten metal is poured over it.

Features: It can obtain castings with extremely high dimensional accuracy and very good surface finish, and can cast parts with extremely complex shapes that are difficult to process by other methods. It is almost applicable to all alloys, especially suitable for high-melting-point and hard-to-machine alloys. However, the process is cumbersome, the production cycle is long, and the cost of a single casting is high.

Main applications: Aerospace engine turbine blades, golf club heads, medical devices, gears, handicrafts, etc.

Description: Abbreviated as die casting. The principle is that under high pressure, molten metal is filled into the cavity of a precise metal mold at high speed and then rapidly cooled and solidified under pressure to form a casting. Molds are usually made of heat-resistant alloy steel and can be reused.

Features: Extremely high production efficiency, suitable for mass production; The castings have high dimensional accuracy, good surface finish and can produce thin-walled complex parts. But the equipment and molds are extremely expensive; It is usually only applicable to low-melting-point alloys (such as zinc, aluminum, and magnesium alloys); Due to the fast filling speed, the gas in the cavity is difficult to be discharged, and the castings are prone to porosity. Generally, heat treatment cannot be carried out.

Main applications: Automotive parts (such as transmission cases), 3C product shells (mobile phones, laptops), toy models, daily hardware parts.

Description: Broadly speaking, gravity casting refers to the process in which molten metal fills a mold under the influence of the Earth's gravity. However, it usually specifically refers to metal mold casting, that is, a casting method that uses a metal mold (referred to as "permanent mold") and relies on the gravity of the molten metal itself to fill the cavity. Molds can be reused hundreds to tens of thousands of times.

Features: Due to the rapid cooling of the metal mold, the casting structure is dense and has good mechanical properties. The dimensional accuracy and surface quality are superior to sand casting but inferior to die casting. One type multiple casting, with relatively high production efficiency. However, the cost of metal molds is higher than that of sand molds. Poor air permeability and high requirements for mold exhaust. It is not suitable for parts with extremely complex shapes.

Main applications: Small and medium-sized castings of non-ferrous metals with high mechanical performance requirements, such as aluminum alloy wheels, engine cylinder heads, pistons, and brake hubs.

| Main Feature | Typical Application Fields | |

| Gray Cast Iron | Low cost, wear-resistant and shock-absorbing, but brittle | Engine block, machine tool bed, pipeline |

| Spheroidal Graphite Cast Iron | High strength, good toughness and excellent comprehensive performance | Crankshafts, gears, and heavy mechanical components |

| Cast Steel | High strength, good toughness and impact resistance | Pressure vessels, power station equipment, structural components |

| Stainless Steel | Corrosion-resistant, heat-resistant and aesthetically pleasing | Chemical equipment, food machinery, medical devices |

| Aluminum Alloy | Light in weight, corrosion-resistant and good in heat conduction | Automobile parts, electrical appliance casings, aerospace components |

| Copper Alloy | Wear-resistant, corrosion-resistant and with good thermal conductivity | Bearings, valves, ship accessories |

| Magnesium Alloy | Extremely light and with high specific strength | 3C product shells, aerospace parts |

| Zinc Alloy | It has excellent castability, can be electroplated and is low in cost | Toys, hardware, zippers |

| Titanium Alloy | It has extremely high specific strength, excellent corrosion resistance and a very high cost | Aerospace engines, human implants |

Copyright © Dongguan Yuanji Technology Co., Ltd. All Rights Reserved - Privacy Policy