Mail Us: [email protected]

Call For Us: +86-13929487727

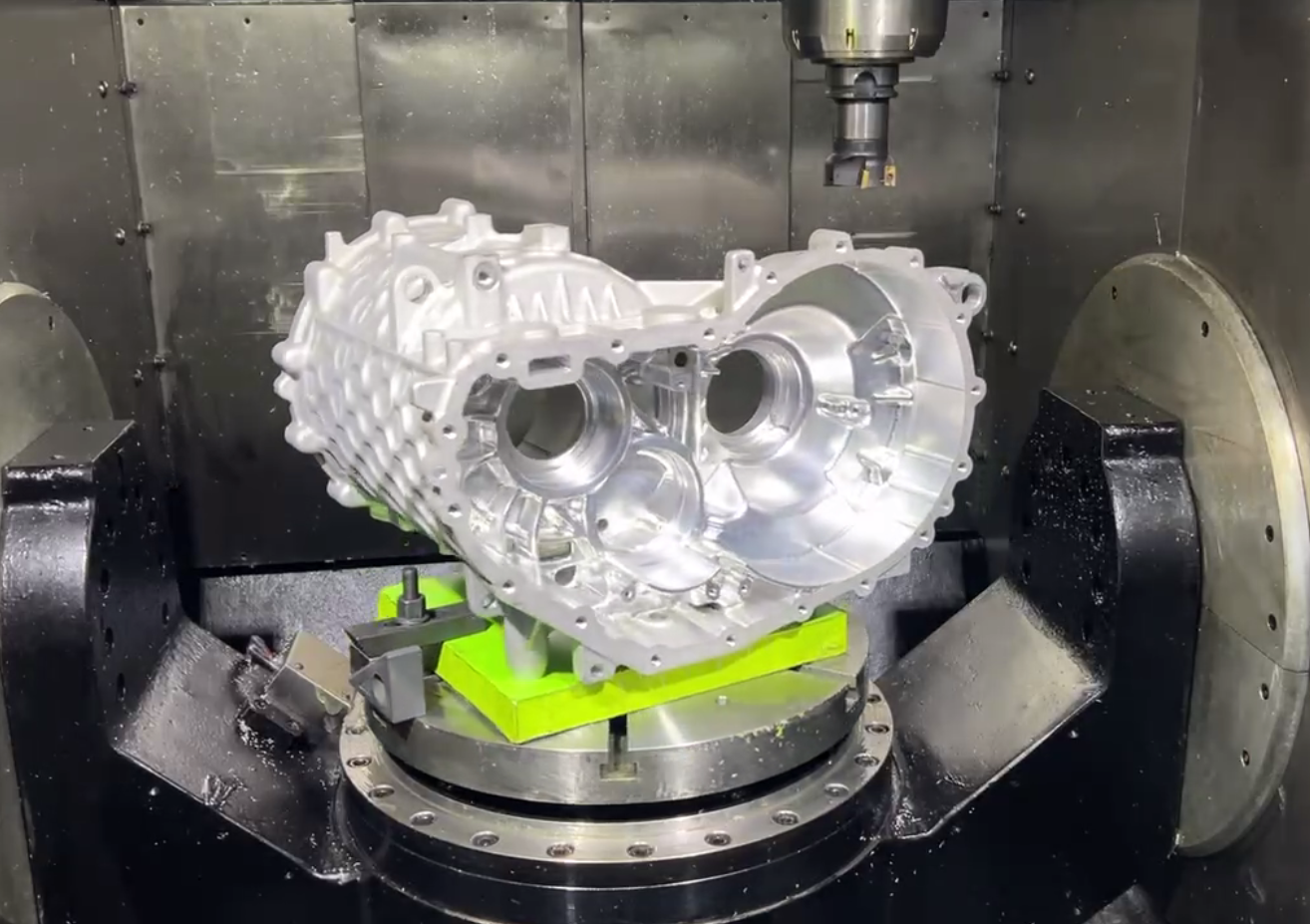

CNC 5-axis machining refers to an advanced manufacturing technology that, on the basis of the traditional three-dimensional linear motion coordinates (X, Y, Z), adds two rotational motion coordinates (two of A, B, and C), enabling the tool to process from any direction of the workpiece.

1.Five axes: three linear axes (X, Y, Z) + two rotational axes.

2.Common combinations of rotating shafts:

In simple terms, it is an "all-powerful engraver". The tool can approach any surface of the workpiece without the need for multiple re-clamping as in a three-axis machine tool.

| Working Principle | Advantage | Disadvantage | |

| Table-Table | Both rotating axes (such as the A-axis and the C-axis) are on the worktable, driving the workpiece to rotate and tilt. | The structure is relatively simple, with strong load-bearing capacity, and is suitable for processing small and medium-sized boxes, impellers and other parts. | The worktable has a limited load-bearing capacity, and its rotation range may be interfered with by the workpiece. |

| Head-Head | Both rotating shafts are on the spindle head, driving the tool to swing and rotate. The workbench is fixed. | It is suitable for processing large and heavy workpieces (such as molds), with the workpieces remaining stationary. | The spindle head has a complex structure, high manufacturing cost and may have slightly weaker rigidity. |

| One Swing Table and One Swing Head (hybrid type) | One rotating axis is on the worktable (such as the C-axis), and the other is on the spindle head (such as the B-axis). | It takes into account both flexibility and a certain load-bearing capacity, and is widely applied. | Programming and post-processing are relatively complex. |

The core value of 5-axis machining is far more than just "five surfaces in one clamping". Its core advantages are reflected in:

1.One clamping, complete the processing of complex geometric shapes:

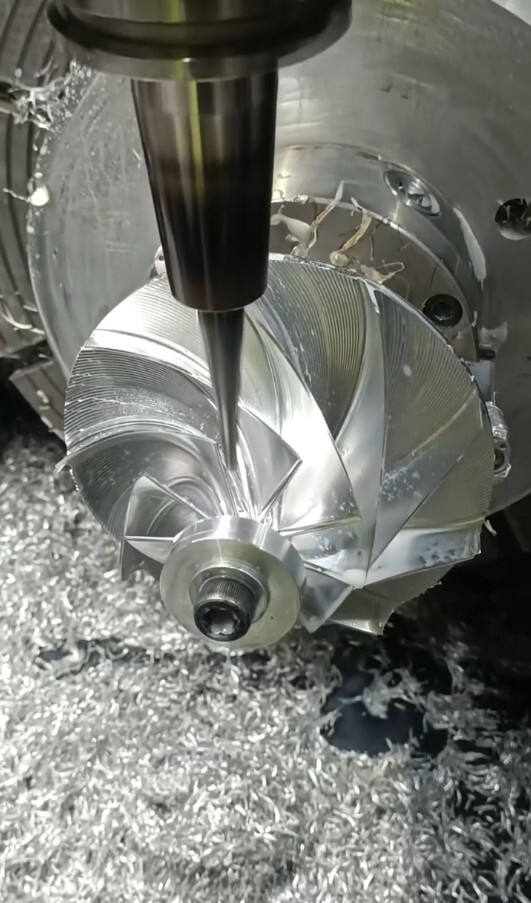

·This is the most intuitive advantage. There is no need for multiple re-clamping, which avoids repeated positioning errors and ensures extremely high overall accuracy. This is the only option for complex parts such as aircraft skins, impellers, turbines, and medical devices.

2.Improve processing quality and surface finish:

·By rotating the axis, the side edge of the tool can be used for cutting (side milling), rather than always using the point at the bottom of the tool for cutting (point milling). Side milling has a higher chip removal rate, more uniform force distribution on the tool, and can achieve better surface quality.

3.Significantly reduce tool length and enhance processing stability:

·By adjusting the Angle of the workpiece, the tool can approach the processing area with the shortest overhang length. The shorter the cutting tool, the stronger its rigidity and the less vibration it generates, thus enabling greater cutting parameters, higher machining accuracy and longer tool life.

4.Achieve efficient cutting:

·By maintaining the optimal cutting Angle between the tool and the workpiece, a greater material removal rate (MRR) can be achieved. For instance, when processing deep cavities, by tilting the workpiece, a shorter ball cutter can be used instead of a long-edge tool for efficient cutting.

Our CNC processes are applicable to various materials, including mechanical-grade metals and plastics. Whether you need precisely machined aluminum parts or other materials, we can produce accurate rapid prototypes and small-batch production runs to meet your requirements. The following are some common materials:

| Material Series | Surface Treatment | |

| Aluminum | AL2011, AL2024, AL5052, AL6061, AL6063, AL6082, AL7075 | Sandblast, Color Anodized, Chemical Film, Brush, Polishing, Chrome Plated, Powder Coated, Laser Logo, Screen Printing |

| Steel Alloy | Q235, 1018, SPCC, A3, #45, SCM435, 40Cr, 4140, S2, D2, Cr2, Y13, Y15, 1.4301, 1.0570, 20MnB, 420C, 65Mn, 1020 | Zinc Plated, Black Oxide, Nickel Plated, Chrome Plated, Carburized, Heat treatment, Powder Coated, Painting, Mirror Polish, Carbon Pattern |

| Stainless Steel | SS301, SS303, SS304, SS316, SS316L, 17-4PH, 430, 440C, 420, 421, 321 | Polishing, Passivated, Blasting, Laser Engrave, Electrophoresis Black, Chrome Plated, Chrome Plated, Electrolytic Polishing, QPQ Black |

| Copper/Brass/Titanium | Brass H59, C1100, C3600, C2800, Red Copper, C93200 | Nickel Plated, Chrome Plated, Electrophoresis Black, Brush, Lacquer, Tin Plated |

| Plastic | ABS, PP, PC, POM, PEEK | Polishing |

Our factory has always been dedicated to product development services and manufacturing production. Whether you only have concept sketches or need structural optimization, our team of engineers can work closely with you to provide services such as DFM (Manufacturability Analysis), 3D modeling, and drawing optimization, ensuring that your design is both innovative and manufacturable, saving you precious time and costs.

Zero-risk prototyping: We break the minimum order quantity barrier of traditional manufacturing and support single-piece prototypes or small-batch production. You can try and make mistakes at zero cost, verify designs, test functions, and showcase ideas at the lowest cost, without fearing inventory pressure, making product iterations more agile.

Aerospace (engine blades, structural components), medical devices (implants, bones), energy (impellers, turbines), high-precision molds, scientific research instruments, etc. Oil pan, Forced Induction, transmission gearbox, Gasoline engine housing, intake manifold, exhaust manifold, Gearbox accumulator housing, Steering column, Billet collector, Compressor centrifuge impeller, motor shell, etc.

Copyright © Dongguan Yuanji Technology Co., Ltd. All Rights Reserved - Privacy Policy