Mail Us: [email protected]

Call For Us: +86-13929487727

Home / Products / 3D Printing

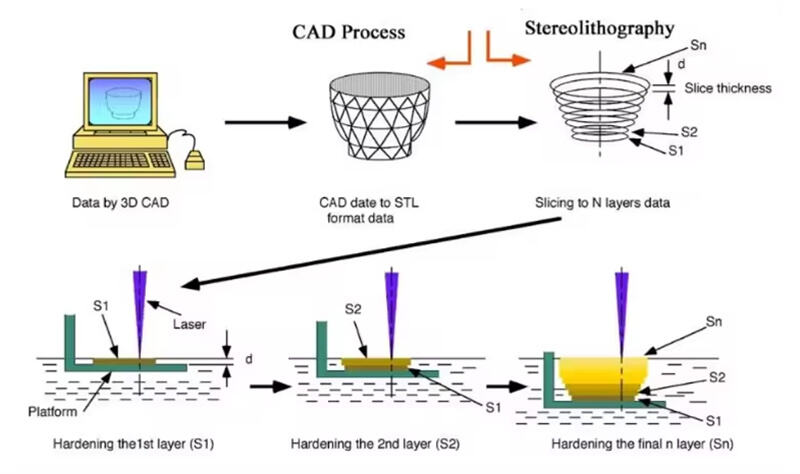

3D printing, scientifically known as additive manufacturing, is a manufacturing technology that is completely different from traditional cutting processing (subtractive manufacturing) and mold forming (such as casting and forging). The core principle is: by layering materials, physical objects are directly constructed from three-dimensional digital models.

Modeling→Slicing→Printing→Post-Processing

Description of the main 3D printing process technology

1. Fused Deposition Modeling (FDM) - The most popular

Working principle: Thermoplastic engineering plastic (such as PLA, ABS) filaments are heated and melted in the print head. The nozzle moves along the cross-sectional contour, extruding the molten material and depositing it at the designated position, where it is instantly cooled and solidified. After one level is completed, the platform descends and proceeds to the next level.

2. Light Curing Molding (SLA) - High precision

Working principle: Liquid photosensitive resin is used as the material. In the liquid tank, the ultraviolet laser beam scans the resin surface along the cross-sectional contour. The resin in the scanned area rapidly photo-polymerizes and solidifies to form a layer. The platform was upgraded to cover the surface with new liquid resin, and the laser continued to scan and cure the next layer.

3. Selective Laser Sintering (SLS) - Manufacturing of functional components

Working principle: It uses powdered materials (such as nylon, metal, etc.) as raw materials. The powder scraping roller first spreads a thin layer of powder on the forming platform. A high-power laser beam selectively scans the powder according to the cross-sectional contour, causing it to sinter (melt and fuse) together. After the first layer is completed, the platform descends, new powder is applied, and the process is repeated until it is finished. The unsintered powder serves a supporting function and can be recycled.

4. Metal 3D Printing (DMLS/SLM) - Industrial grade

Working principle: Similar to SLS, but specifically using metal powder. The laser beam completely melts the metal powder particles, causing them to fuse and form a dense metal entity. SLM (Selective Laser Melting) requires the powder to be completely melted, while DMLS (Direct Metal Laser Sintering) is to melt and bond the surface of powder particles.

5. Multi-jet Fusion (MJF) - High-speed production

Working principle: First, lay a layer of powder. Then, the nozzle, like an inkjet printer, sprays the molten agent in the area that needs to be formed and the refiner in the edge area. After that, the entire layer is illuminated by an infrared heating lamp. The area with the molten agent absorbs energy and melts and solidifies, while the area with the refiner does not melt.

|

Advantage |

|

|

DesignFreedom |

It can easily manufacture complex structures, internal cavities and integrated components that cannot be processed by traditional techniques. |

|

NoMoldsRequired |

Single-piece or small-batch production costs are extremely low, making it a perfect solution for prototype verification and personalized customization. |

|

RapidPrototyping |

The cycle from design to physical product has been greatly shortened. |

|

StrongCustomizationCapability |

Easily meet personalized demands in fields such as healthcare and consumer goods. |

|

Operating Cost |

The costs of electricity and gas are high |

|

Disadvantage |

|

|

High Batch Cost |

When mass-produced, the speed and cost cannot be compared with traditional injection molding, die-casting and other methods. |

|

Surface Quality |

There are usually layering patterns, and post-treatment is required to achieve a smooth surface |

|

Dimensional Limit |

Limited by the size of the printer's forming space. |

A: Yes, we are factory in Guangdong, China.

A:

Machining is 3-7 days for sample, 15-20 days for batch according to quantity;

Molding is 25 days for sample, 15-20 days for bulk.

A: Yes, we can, it need the sample fee, but can be refunded when place bulk order.

A: We offer flexible payment methods including bank transfer (TT), PayPal, Western Union, and Letters of Credit to facilitate secure global transactions. 30%-50% in advance, pay balance before shipping.

A: Yes, we can accommodate custom logos and packaging designs based on order quantities. Please discuss your specific needs with our sales team.

A: Yes, we support OEM/ODM customization based on your technical drawings, 2D/(PDF/CAD)3D(IGES/STEP).

Copyright © Dongguan Yuanji Technology Co., Ltd. All Rights Reserved - Privacy Policy