Mail Us: [email protected]

Call For Us: +86-13929487727

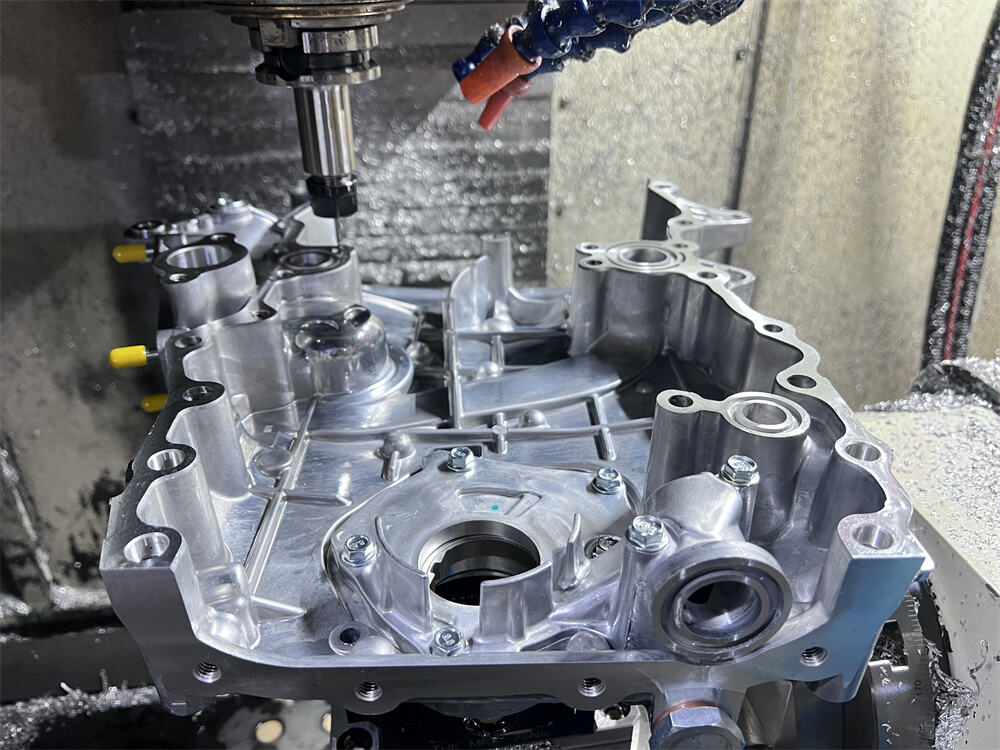

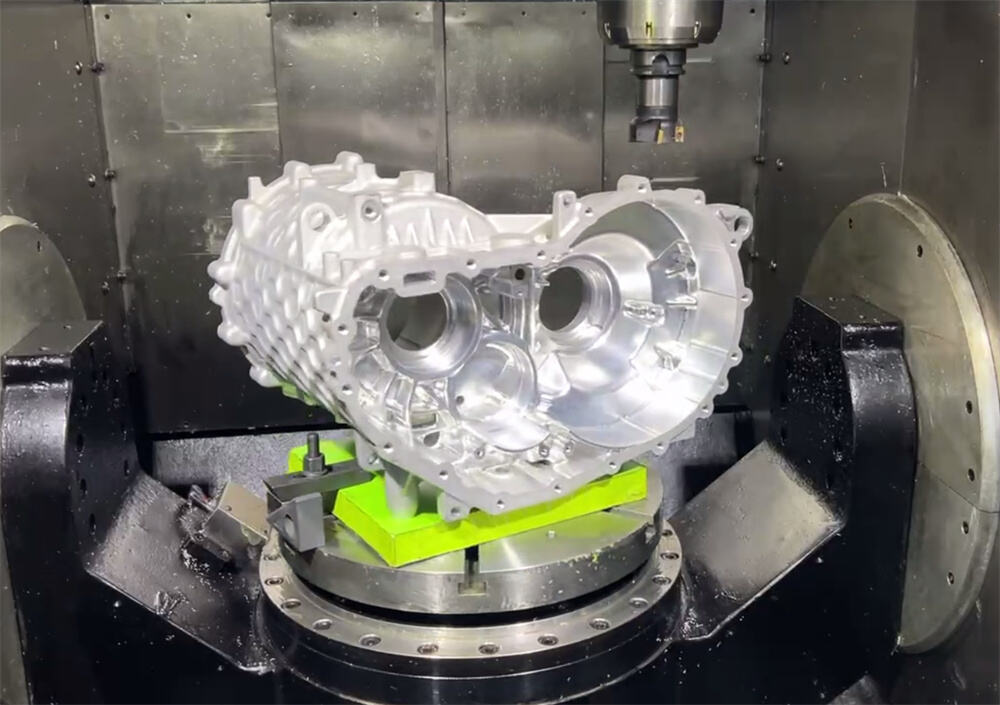

Breaking the boundaries of traditional processing, our turning and milling compound center redefines efficiency and precision with the "one-time forming" technology

High Precision |

+-0.005mm |

Material |

①Metal: Aluminum alloy, Stainless steel, Mild steel, Carbon steel, Harded steel, Brass, Copper, Bronze, etc. |

Certification |

ISO9001, RoHS |

Service |

OEM ODM service |

Machine |

3-4-5 Axis CNC Machining Centre |

Packaging Details |

Standard: Pearl cotton and bubble bag, carton box and seal Custom aircraft box, Color packaging box |

Delivery Time |

3-5 days for sample, 15-20 days for large quantity |

Payment Terms |

Can accept small quantity order, 30%-50% deposit |

Supply Ability |

10000+ pieces |

Surface Treatment |

Sandblast, Color anodized, Laser logo, Zinc plated, Heat treatment, Powder coating, Chrome plating, Tin plating, Brush, Lacquer, Polish, blasting, etc |

Application |

Auto/Bicycle/Electronic/Furniture/Machinery Equipment |

CNC turning and Milling Compound

1.Efficiency improvement: All processes can be completed in one clamping, avoiding multiple positioning errors and shortening the delivery cycle by more than 50%.

2.Cost optimization: Reduce equipment investment and manual intervention, suitable for medium and small batch multi-variety production, and lower the overall cost.

3.Quality Assurance: By eliminating the reference conversion error through integrated processing, the surface roughness can reach Ra0. 8μm.

4.Flexible adaptation: Supports multiple materials such as stainless steel, titanium alloy, and engineering plastics, meeting cross-industry demand

|

Characteristic |

Detailed Description |

|

Multi-axis motion |

5-axis linkage control supports simultaneous processing of multiple procedures such as turning, milling, drilling and tapping, reducing clamping errors. |

|

High precision |

The positioning accuracy is±0.003mm, and the repeat positioning accuracy is±0.001mm. It is suitable for precision medical devices, aerospace components and other fields. |

|

Intelligent tool changing |

Equipped with a 24-station tool magazine, it supports automatic tool changing and is compatible with turning tools, milling cutters, drills, etc., increasing processing efficiency by more than 30%. |

|

Combined machining |

The turning and milling integrated molding can handle complex curved surfaces, eccentric structures, inclined holes and other processes that are difficult to complete with traditional machine tools. |

|

Numerical control system |

Equipped with an open CNC system, it supports seamless integration with CAD/CAM, is easy to program, and can meet personalized customization needs. |

|

Rigid construction |

The cast iron bed and linear guide rails have strong shock resistance, ensuring stability during long-term high-load operation. |

A: Yes, we are factory in Guangdong, China.

A:

Machining is 3-7 days for sample, 15-20 days for batch according to quantity;

Molding is 25 days for sample, 15-20 days for bulk.

A: Yes, we can, it need the sample fee, but can be refunded when place bulk order.

A: We offer flexible payment methods including bank transfer (TT), PayPal, Western Union, and Letters of Credit to facilitate secure global transactions. 30%-50% in advance, pay balance before shipping.

A: Yes, we can accommodate custom logos and packaging designs based on order quantities. Please discuss your specific needs with our sales team.

A: Yes, we support OEM/ODM customization based on your technical drawings, 2D/(PDF/CAD)3D(IGES/STEP).

Copyright © Dongguan Yuanji Technology Co., Ltd. All Rights Reserved - Privacy Policy