Mail Us: [email protected]

Call For Us: +86-13929487727

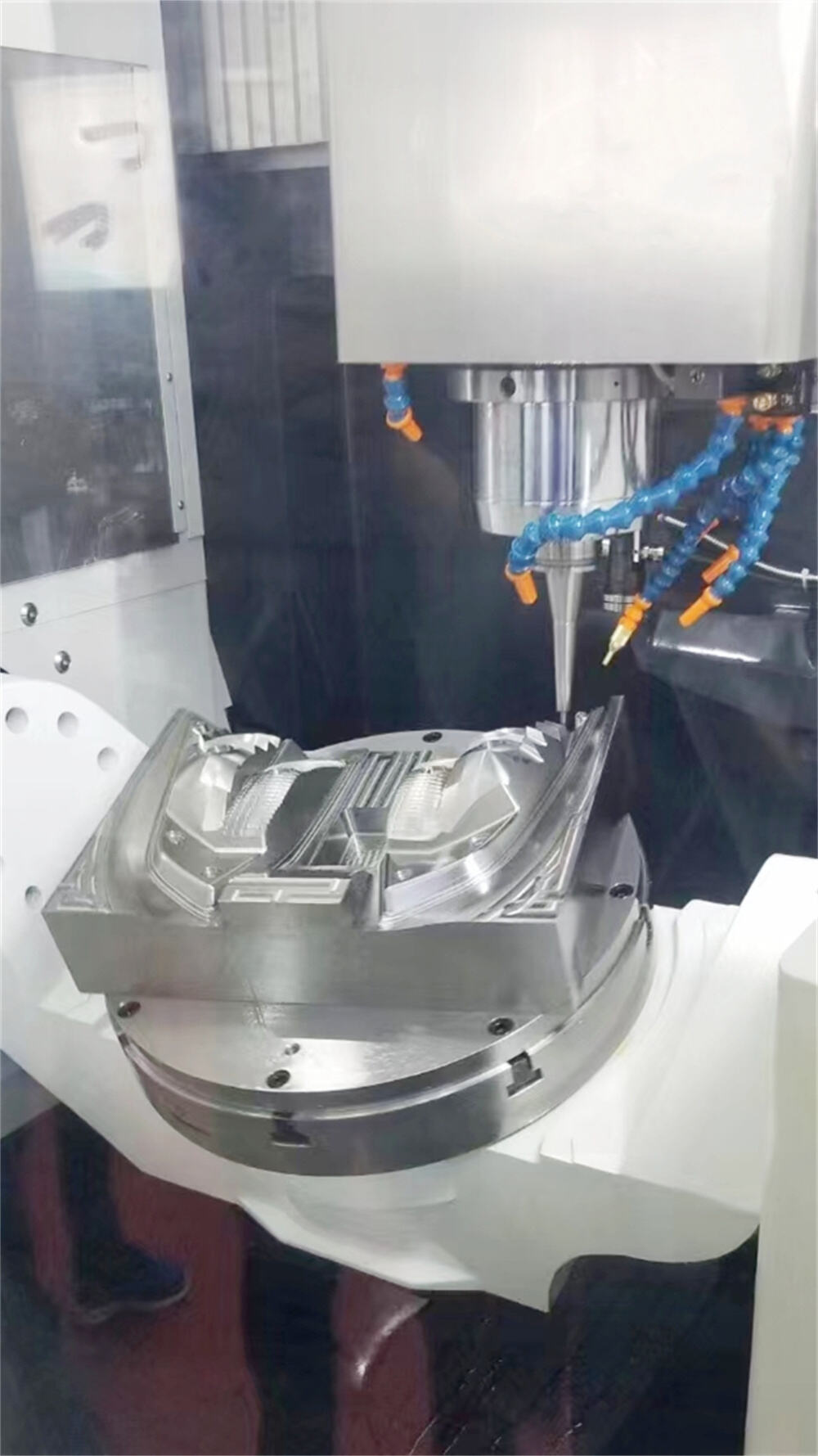

Five-axis machining features high precision, high flexibility and high efficiency, and is often used in the manufacturing of turbine blades, engine casings, aviation structural components, etc

High Precision |

+-0.005mm |

Material |

①Metal: Aluminum alloy, Stainless steel, Mild steel, Carbon steel, Harded steel, Brass, Copper, Bronze, etc. |

Certification |

ISO9001, RoHS |

Service |

OEM ODM service |

Machine |

3-4-5 Axis CNC Machining Centre |

Packaging Details |

Standard: Pearl cotton and bubble bag, carton box and seal Custom aircraft box, Color packaging box

|

Delivery Time |

3-5 days for sample, 15-20 days for large quantity |

Payment Terms |

Can accept small quantity order, 30%-50% deposit |

Supply Ability |

10000+ pieces |

Surface Treatment |

Sandblast, Color anodized, Laser logo, Zinc plated, Heat treatment, Powder coating, Chrome plating, Tin plating, Brush, Lacquer, Polish, blasting, etc |

Application |

Auto/Bicycle/Electronic/Furniture/Machinery Equipment |

The core advantages of five-axis machining

|

Advantage |

Detailed Description

|

|

Processing of complex curved surfaces |

It can complete the high-precision processing of complex curved surfaces such as impellers, propellers and aviation structural components at one time, avoiding multiple clamping errors. |

|

High precision & high surface finish |

The cutting tool can always optimize the cutting Angle, reduce the tool contact mark, and the surface roughness can reach Ra0.4μm, making it suitable for precision parts. |

|

Reduce the number of clamping times |

One-time positioning can complete multi-faceted processing, shorten the production cycle and increase efficiency by 30% to 50%. |

|

Extend the service life of cutting tools |

By optimizing the cutting Angle of the tool, local wear is reduced and processing costs are lowered.

|

|

High flexibility

|

Supports efficient cutting of difficult-to-machine materials such as titanium alloys, superalloys, and composite materials. |

A: Yes, we are factory in Guangdong, China.

A:

Machining is 3-7 days for sample, 15-20 days for batch according to quantity;

Molding is 25 days for sample, 15-20 days for bulk.

A: Yes, we can, it need the sample fee, but can be refunded when place bulk order.

A: We offer flexible payment methods including bank transfer (TT), PayPal, Western Union, and Letters of Credit to facilitate secure global transactions. 30%-50% in advance, pay balance before shipping.

A: Yes, we can accommodate custom logos and packaging designs based on order quantities. Please discuss your specific needs with our sales team.

A: Yes, we support OEM/ODM customization based on your technical drawings, 2D/(PDF/CAD)3D(IGES/STEP).

Copyright © Dongguan Yuanji Technology Co., Ltd. All Rights Reserved - Privacy Policy