Mail Us: [email protected]

Call For Us: +86-13929487727

High-precision turn-mill machined parts with tight tolerances. Custom CNC turn milling solutions for automotive, industrial, robotics, and OEM applications.

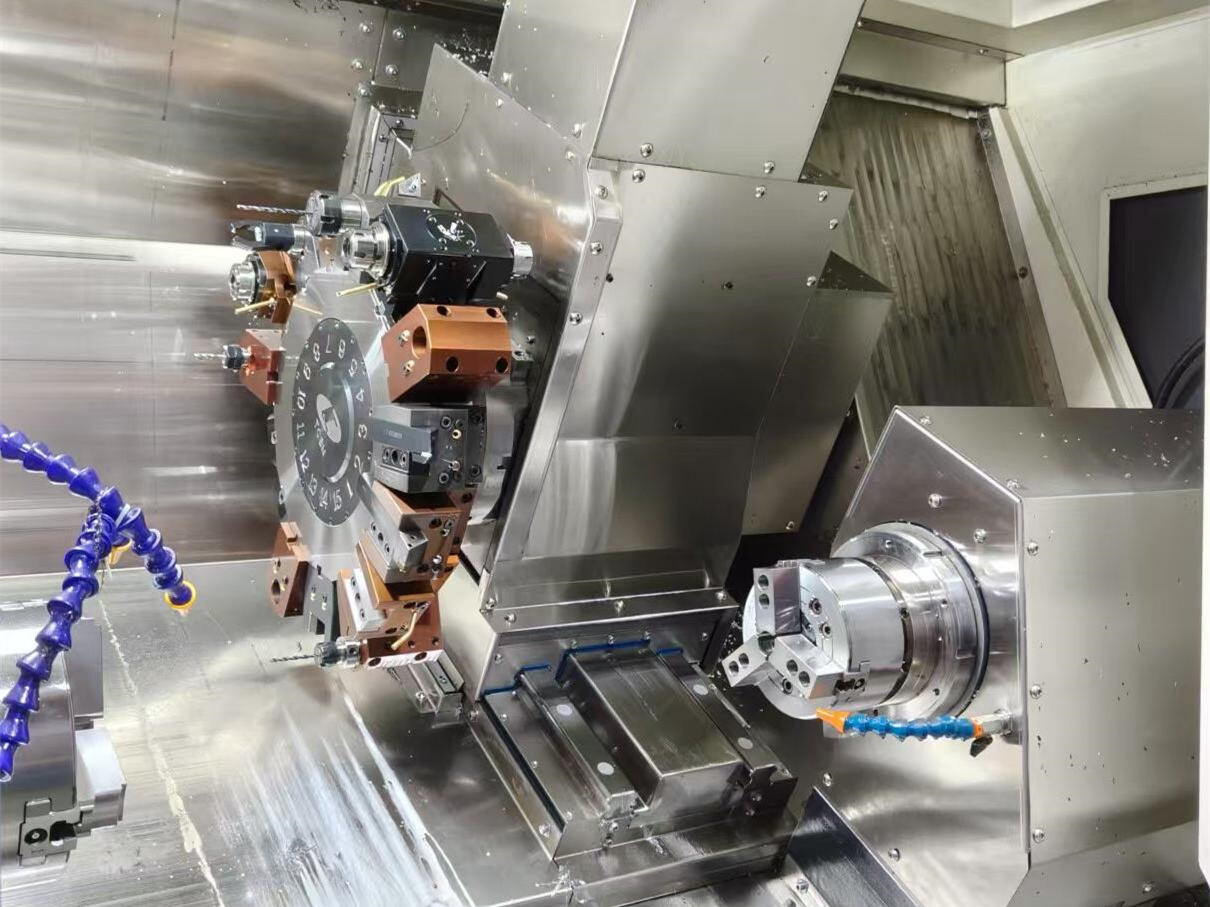

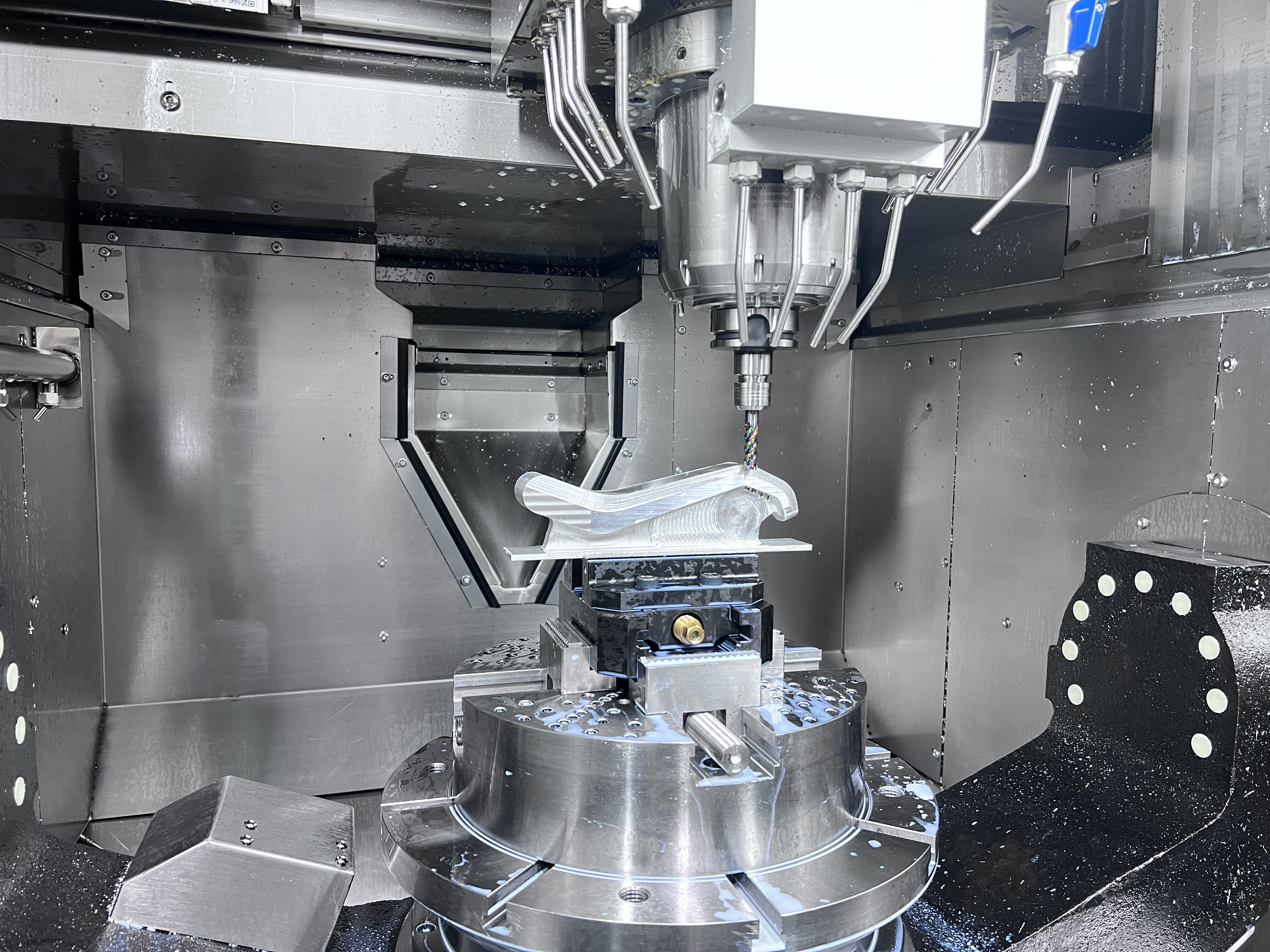

Our turn-mill machined parts are manufactured using advanced CNC turn milling technology, which integrates turning and milling operations into a single machining process.

This combined approach significantly reduces multiple setups, improves dimensional accuracy, and ensures consistent surface quality for complex components.

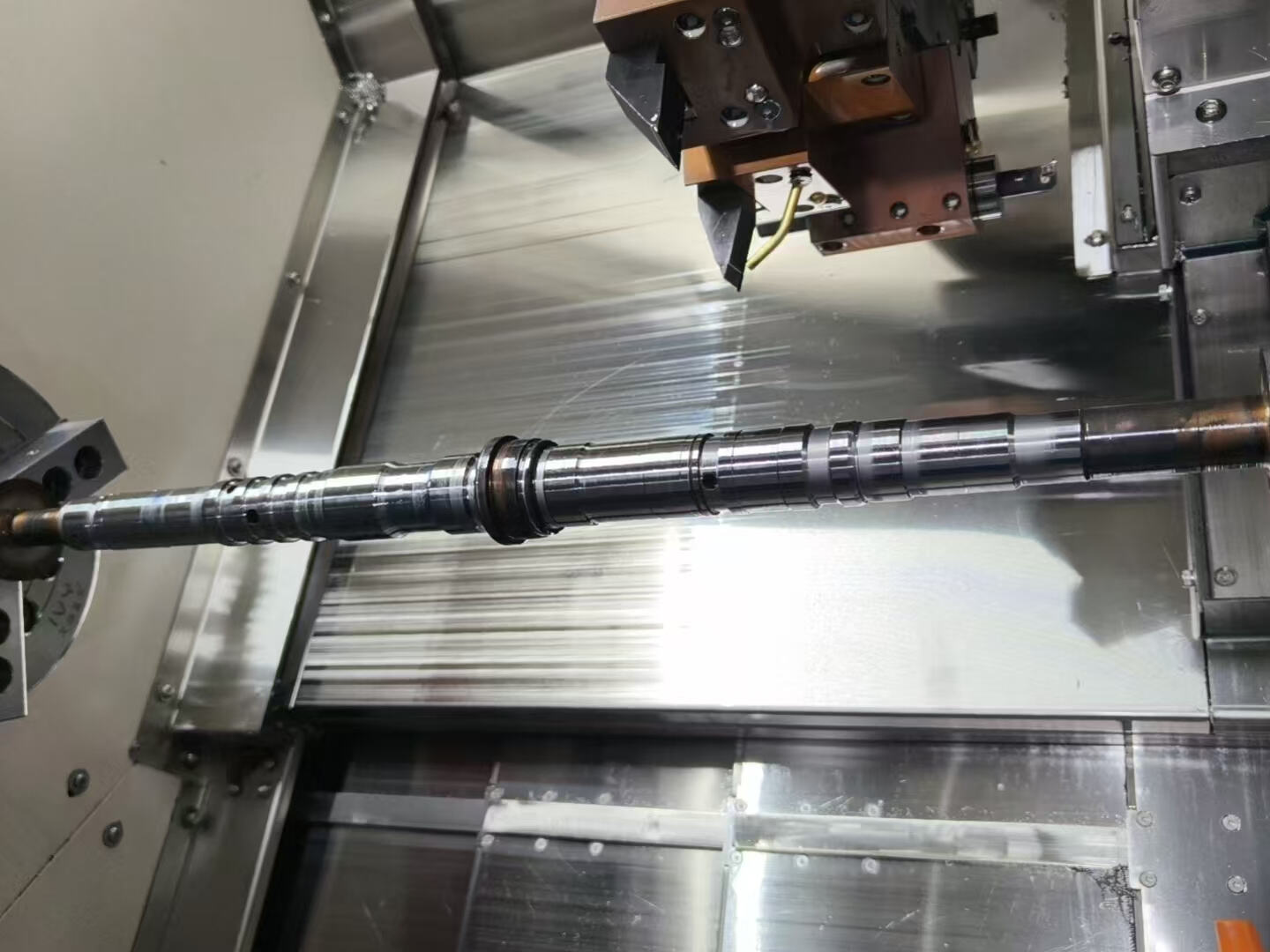

Turn-mill machining is especially suitable for parts that require both rotational symmetry and milled features, such as slots, holes, keyways, threads, and complex contours.

By completing multiple operations in one setup, we are able to achieve tighter tolerances, better concentricity, and higher production efficiency.

We provide custom CNC turn milling services for a wide range of industries, supporting prototypes, small batches, and mass production. All parts are manufactured strictly according to customer drawings and specifications.

|

Processing Technology

|

CNC Turning, CNC Milling, Drilling, Tapping, Boring, Grinding |

|

Machining Accuracy

|

±0.005mm - ±0.05mm (adjustable according to material and structure) |

|

Material: |

①Metal: Aluminum alloy, Stainless steel, Mild steel, Carbon steel, Harded steel, Brass, Copper,Bronze,etc. ②Plastic: PMMA, POM, PP, PC, ABS, Nylon, Resin, PA, TPU, Acrylic, etc. |

|

Certification: |

ISO9001, RoHS |

|

Service: |

OEM ODM service |

|

Machine: |

3-4-5 Axis CNC Machining Centre |

|

Packaging Details: |

Standard: Pearl cotton and bubble bag, carton box and seal Custom aircraft box, Color packaging box

|

|

Delivery Time: |

3-5 days for sample, 15-20 days for large quantity |

|

Payment Terms: |

Can accept small quantity order, 30%-50% deposit |

|

Supply Ability: |

10000+ pieces |

|

Surface Treatment |

Sandblast, Color anodized, Laser logo, Zinc plated, Heat treatment, Powder coating, Chrome plating, Tin plating, Brush, Lacquer, Polish, blasting, etc |

|

Maximum Processing Size |

Diameter: 2-500mm, length: 2-1500mm |

|

File Format |

STEP, IGES, PDF, DWG, STP |

Advantages of Turn-Mill Machining

CNC Turn Milling Capability

Our manufacturing facility is equipped with multi-axis CNC turn-mill centers, enabling simultaneous turning, milling, drilling, and tapping operations.

This capability allows us to produce complex turn-mill components with high accuracy and excellent repeatability.

Supported capabilities include:

Our customers are spread across Europe, America, Asia, Australia and other regions, and our products are widely used in high-end equipment manufacturing and scientific research projects.

Quality Control & Inspection

Quality is integrated throughout the entire production process.

Each turn-mill machined part undergoes inspection to ensure it meets customer specifications and functional requirements.

Our quality control includes:

A: Yes, we are factory in Guangdong, China.

A:

Machining is 3-7 days for sample, 15-20 days for batch according to quantity;

Molding is 25 days for sample, 15-20 days for bulk.

A: Yes, we can, it need the sample fee, but can be refunded when place bulk order.

A: We offer flexible payment methods including bank transfer (TT), PayPal, Western Union, and Letters of Credit to facilitate secure global transactions. 30%-50% in advance, pay balance before shipping.

A: Yes, we can accommodate custom logos and packaging designs based on order quantities. Please discuss your specific needs with our sales team.

A: Yes, we support OEM/ODM customization based on your technical drawings, 2D/(PDF/CAD)3D(IGES/STEP).

Copyright © Dongguan Yuanji Technology Co., Ltd. All Rights Reserved - Privacy Policy