Mail Us: [email protected]

Call For Us: +86-13929487727

Custom CNC Machining Factory's for Micro Machining Services Customized Size Anodized Aluminum Logo Customized Machining

|

Processing Technology

|

CNC Turning, CNC Milling, Drilling, Tapping, Boring, Grinding |

|

Machining Accuracy

|

±0.005mm - ±0.05mm (adjustable according to material and structure) |

Material: |

①Metal: Aluminum alloy, Stainless steel, Mild steel, Carbon steel, Harded steel, Brass, Copper,Bronze,etc. ②Plastic: PMMA, POM, PP, PC, ABS, Nylon, Resin, PA, TPU, Acrylic, etc. |

Certification: |

ISO9001, RoHS |

Service: |

OEM ODM service |

Machine: |

3-4-5 Axis CNC Machining Centre |

Packaging Details: |

Standard: Pearl cotton and bubble bag, carton box and seal Custom aircraft box, Color packaging box

|

Delivery Time: |

3-5 days for sample, 15-20 days for large quantity |

Payment Terms: |

Can accept small quantity order, 30%-50% deposit |

Supply Ability: |

10000+ pieces |

Surface Treatment |

Sandblast, Color anodized, Laser logo, Zinc plated, Heat treatment, Powder coating, Chrome plating, Tin plating, Brush, Lacquer, Polish, blasting, etc |

Maximum Processing Size |

Diameter: 2-500mm, length: 2-1500mm |

File Format |

STEP, IGES, PDF, DWG, STP |

1. High-precision processing capability

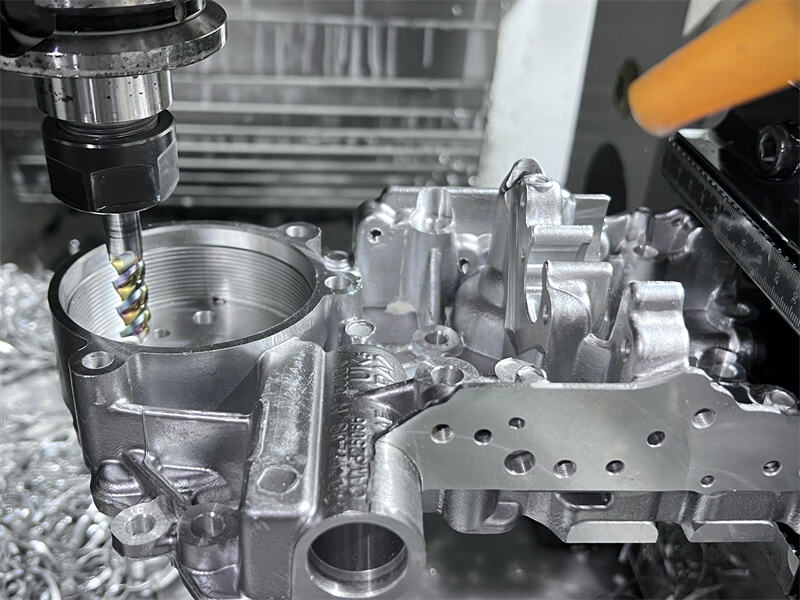

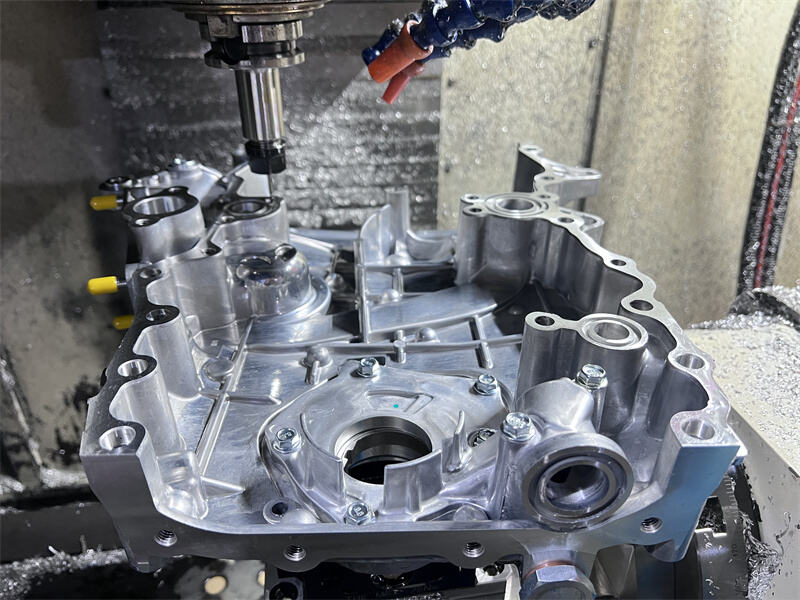

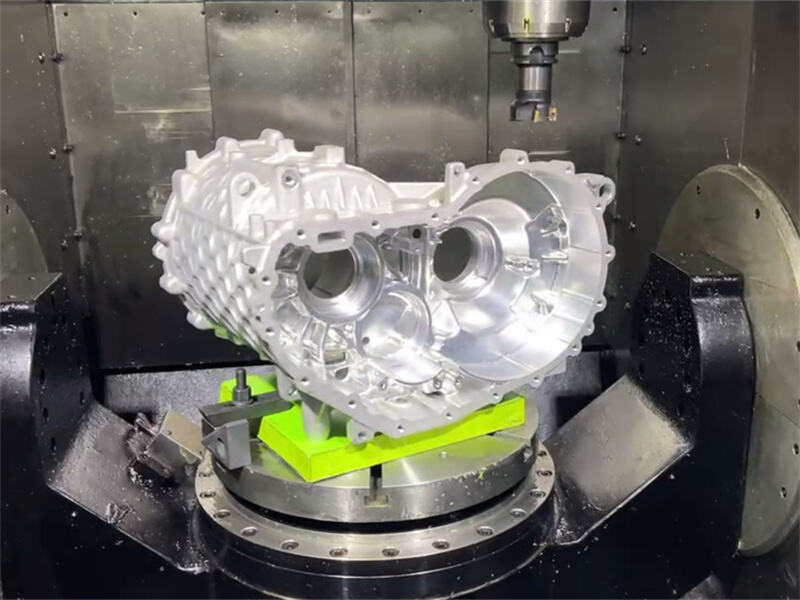

Advanced five-axis machining centers and high-speed CNC lathes are adopted to process complex-structured parts, deep holes, steps and high coaxiality parts, ensuring the stable precision of each batch of products.

2. Customized sizes and complex structures

From micro-parts to large mechanical structural components, whether it's a single sample or mass production, we can precisely process according to the drawings. Supports the processing of parts with complex curved surfaces, multiple holes and multiple cutting surfaces.

3. Diversified materials

Supports processing of aluminum, stainless steel, steel, copper, titanium alloy and engineering plastics to meet the requirements of strength, corrosion resistance, wear resistance and lightweight.

4. Automated production and efficiency improvement

Introduce robot arms for automatic loading and unloading as well as processing procedures to achieve stable batch processing, reduce human errors, and enhance production efficiency and delivery reliability.

5. Complete quality inspection system

Equipped with a three-coordinate measuring machine (CMM), roughness tester, hardness tester and other inspection equipment, we ensure that each batch of parts meets the requirements of the design drawings, and can provide detailed quality inspection reports and third-party inspection services.

6. Rapid sample and batch delivery

The sample processing cycle is short and can be completed within 3 to 7 days. Large orders can be supplied stably as planned to meet the demands of urgent projects.

Automobile parts: shafts, gears, brackets, flanges, couplings, transmission components

Robot and automation equipment parts: robot arm interfaces, locating pins, support components

Industrial mechanical parts: mechanical fixtures, gearboxes, hydraulic parts

Medical instrument parts: surgical instruments, detection devices, precision structural components

Electronic communication accessories: heat sinks, casings, connectors

Aerospace parts: lightweight structural components, precision connecting parts

Our customers are spread across Europe, America, Asia, Australia and other regions, and our products are widely used in high-end equipment manufacturing and scientific research projects.

A: Yes, we are factory in Guangdong, China.

A:

Machining is 3-7 days for sample, 15-20 days for batch according to quantity;

Molding is 25 days for sample, 15-20 days for bulk.

A: Yes, we can, it need the sample fee, but can be refunded when place bulk order.

A: We offer flexible payment methods including bank transfer (TT), PayPal, Western Union, and Letters of Credit to facilitate secure global transactions. 30%-50% in advance, pay balance before shipping.

A: Yes, we can accommodate custom logos and packaging designs based on order quantities. Please discuss your specific needs with our sales team.

A: Yes, we support OEM/ODM customization based on your technical drawings, 2D/(PDF/CAD)3D(IGES/STEP).

Copyright © Dongguan Yuanji Technology Co., Ltd. All Rights Reserved - Privacy Policy