Mail Us: [email protected]

Call For Us: +86-13929487727

High-Precision Aluminum Extruded Profiles Enhanced by CNC Milling, Drilling, and Tapping for Industrial Applications, Electronics, LED & EV

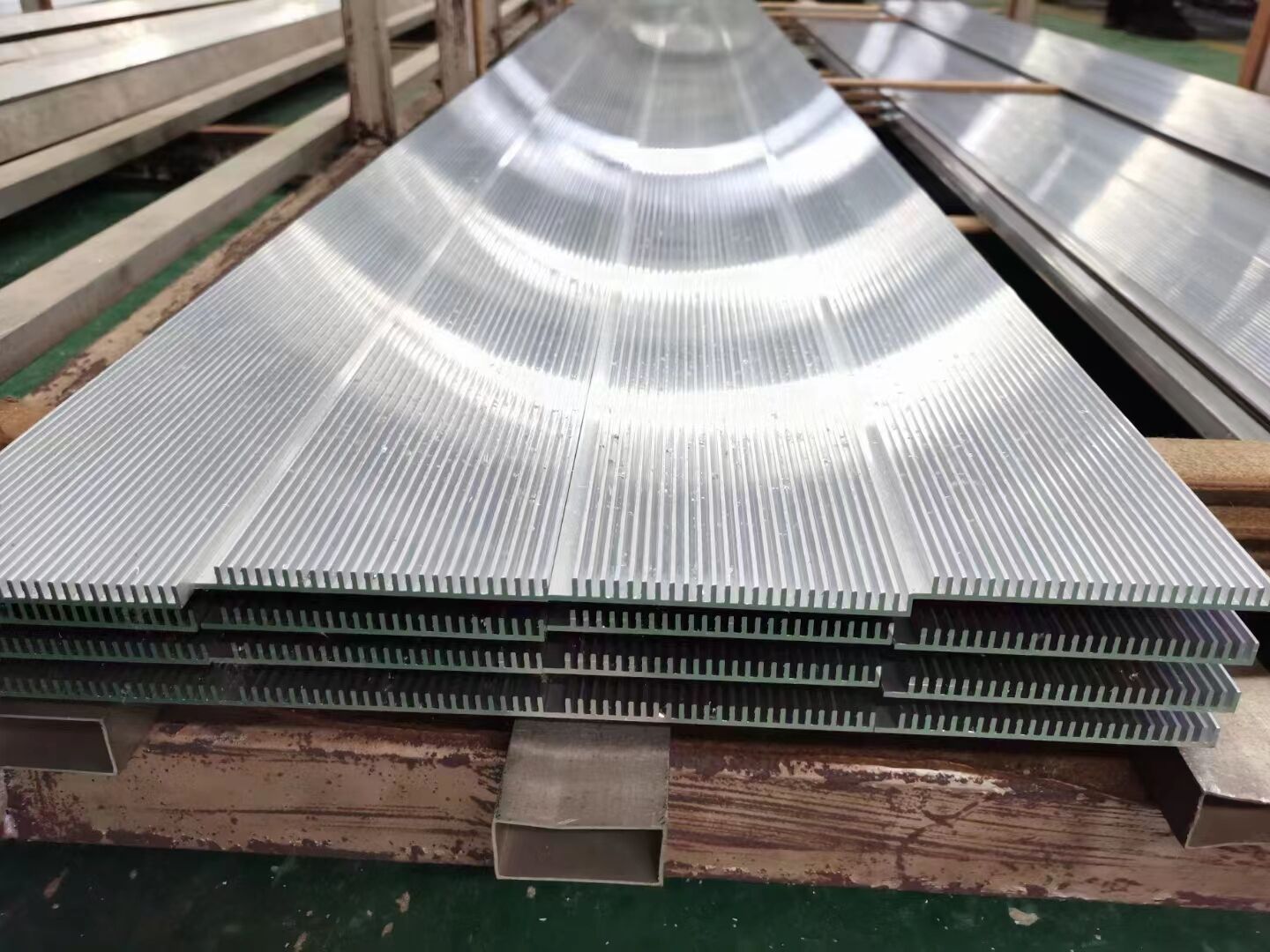

Our aluminum profile products are made through high-strength aluminum alloy extrusion forming technology and undergo secondary fine processing in combination with high-precision CNC machining technology. They are widely used in industrial equipment, automation systems, electronic casings, heat dissipation structures, mechanical frames, transportation equipment and the new energy industry.

By combining the high efficiency of aluminum extrusion molding with the high precision of CNC finishing, we can provide customers with customized aluminum profile solutions that are dimensionally stable, structurally complex, assembly-friendly and have consistent surface quality.

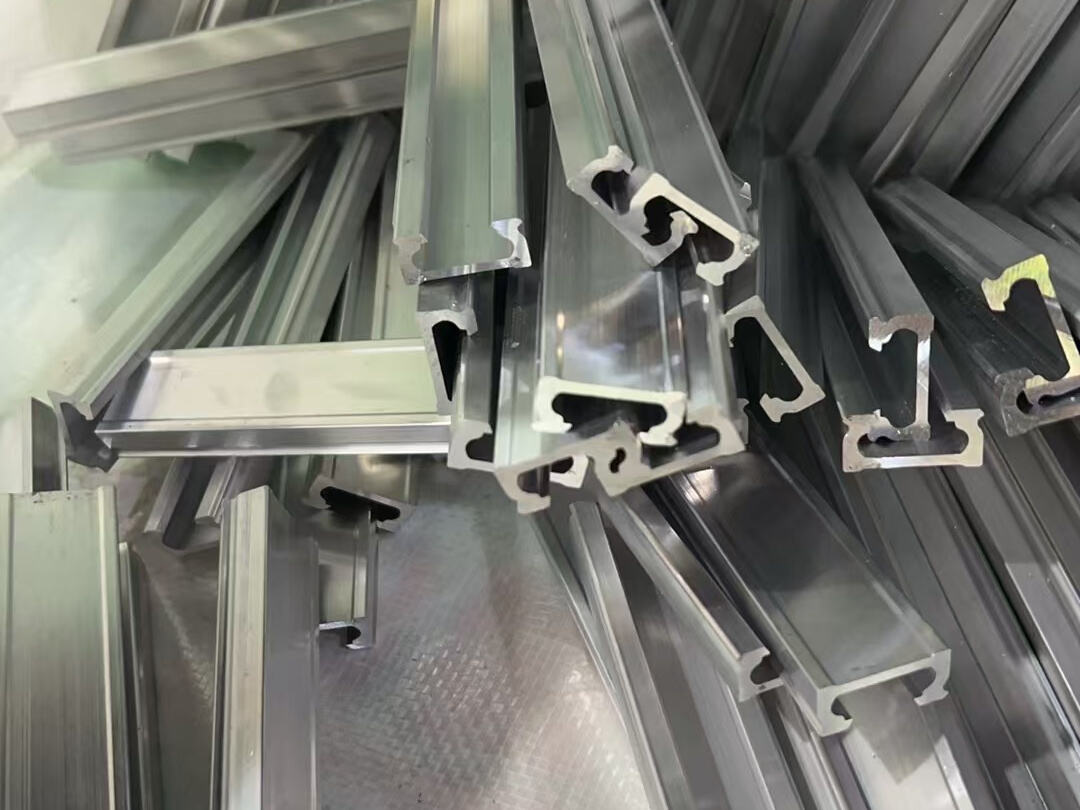

Compared with standard aluminum profiles, our products can achieve more complex cross-sectional structures, stricter tolerance control and more flexible functional integration, significantly reducing the subsequent assembly and secondary processing costs for customers.

Aluminum Extrusion is a forming process in which heated aluminum alloy billets are extruded into specific cross-sectional shapes through custom molds. This process is highly suitable for manufacturing aluminum profile products with long dimensions, complex cross-sections, and stable and consistent batch sizes.

Advantages of extrusion process

Support complex hollow or multi-cavity structure designs

It has a high material utilization rate and is suitable for medium and large-scale production

Good cross-sectional consistency and high structural strength

Customize wall thickness, slot position and reinforcing ribs

It is applicable to commonly used aluminum alloys such as 6061/6063/6082/7075

Common applications of extruded aluminum profiles

Industrial equipment framework

Automated assembly line structure

Electronic and electrical enclosures

LED lighting profiles

Bracket for new energy battery systems

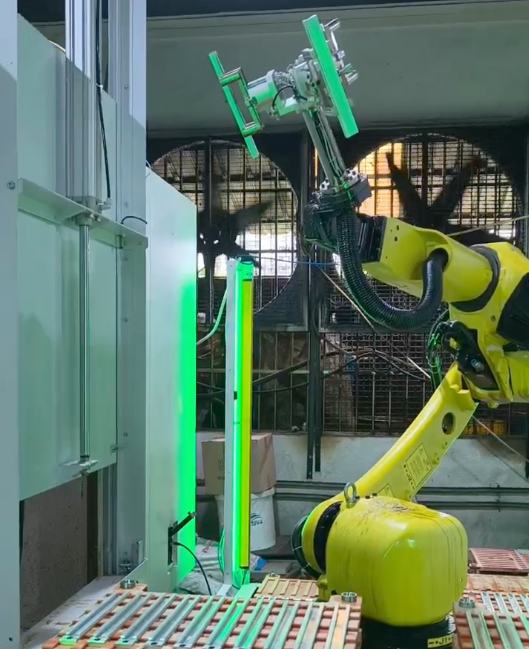

Although the aluminum extrusion process can form complex cross-sections, in terms of high-precision assembly, functional hole positions, thread structures and key assembly surfaces, higher precision still needs to be achieved through CNC machining.

After the aluminum profiles are extruded, we use a multi-axis CNC machining center for secondary processing, including:

CNC Milling, CNC Drilling, CNC Tapping (Tapping), CNC slotting, chamfering and contour processing

The core value brought by CNC machining

Precise hole positions and installation structures

Strict dimensional tolerance control

Enhance assembly consistency and reliability

Support small-batch customization and rapid iteration

Meet the demands of high-end industrial and engineering applications

By combining aluminum extrusion with CNC finishing, we have achieved:

Cost control: Extrusion molding reduces material and processing costs

Structural freedom: CNC machining realizes functional details

Production efficiency: Suitable for the complete cycle from sample to batch

Quality stability: Consistent in size, strength and appearance

This combined process is particularly suitable for customers who have high requirements for strength, precision, appearance and assembly efficiency.

|

Material |

Aluminum 6061/6063/6082/7075 |

|

Forming Process |

Aluminum Extrusion |

|

Finishing Process |

CNC Milling/Drilling/Tapping |

|

Tolerance Range |

±0.05mm to ±0.1mm |

|

Surface Treatment |

Anodizing/Powder Coating/Sandblasting/Laser Engraving/Silk Screen |

|

Color |

Silver/Black/Custom |

|

Application Industries |

Industrial/Automation/Electronics/Energy |

|

MOQ |

100pcs |

|

Drawing Support |

STEP / IGES / PDF |

A: Yes, we are factory in Guangdong, China.

A:

Machining is 3-7 days for sample, 15-20 days for batch according to quantity;

Molding is 25 days for sample, 15-20 days for bulk.

A: Yes, we can, it need the sample fee, but can be refunded when place bulk order.

A: We offer flexible payment methods including bank transfer (TT), PayPal, Western Union, and Letters of Credit to facilitate secure global transactions. 30%-50% in advance, pay balance before shipping.

A: Yes, we can accommodate custom logos and packaging designs based on order quantities. Please discuss your specific needs with our sales team.

A: Yes, we support OEM/ODM customization based on your technical drawings, 2D/(PDF/CAD)3D(IGES/STEP).

Copyright © Dongguan Yuanji Technology Co., Ltd. All Rights Reserved - Privacy Policy