Mail Us: [email protected]

Call For Us: +86-13929487727

Sheet Metal Laser Cut Bend Weld Steel Frame Parts One-Stop Service Metal Stamping CNC Bending Welding Custom Fabrication

Material |

Aluminum alloy, Stainless steel, Mild steel, Carbon steel, Harded steel, Brass, Copper,Bronze,etc. |

|

Main Craft

|

Stamping/Bending/welding/CNC finishing (optional) |

|

Thickness Range

|

0.1-8mm (Special customize) |

Dimensional Precision |

±0.1mm to ±0.2mm (depending on the process) |

Certification |

ISO9001, RoHS |

Service |

OEM ODM service |

Packaging Details |

Standard: Pearl cotton and bubble bag, carton box and seal Custom aircraft box, Color packaging box

|

Payment Terms |

Can accept small quantity order, 30%-50% deposit |

Supply Ability |

1000000+ pieces |

Surface Treatment |

Sandblast, Color anodized, Laser logo, Zinc plated, Heat treatment, Powder coating, Chrome plating, Tin plating, Brush, Lacquer, Polish, blasting, etc |

Application |

Auto/Bicycle/Electronic/Furniture/Machinery Equipment |

Stamping rapid prototyping:High-tonnage presses ensure precise shapes and high efficiency, making them suitable for mass production.

High bending accuracy:The CNC bending machine, in combination with Angle compensation technology, can achieve complex bending structures.

The welding is firm and stable:The introduction of a robot welding system ensures uniform weld seams, high strength, and no false welding.

Deeply customize:Supports OEM/ODM, and can provide complete processing solutions based on samples or 3D drawings.

Strict quality inspection process:online monitoring + full-size inspection to ensure that products meet international standards.

Rich experience in global exports:Familiar with the standards of the European and North American markets, and can provide relevant certification documents.

1. Stamping forming: High efficiency + high consistency

We use high-speed punch presses and custom molds to rapidly form metal sheets, ensuring stable dimensions, smooth edges, and suitability for mass production with controllable costs.

2. CNC bending: Even complex structures can be precisely formed

We have introduced CNC bending machines and Angle compensation systems. Every bending Angle is calculated and tested, ensuring stable precision even through multiple bending processes.

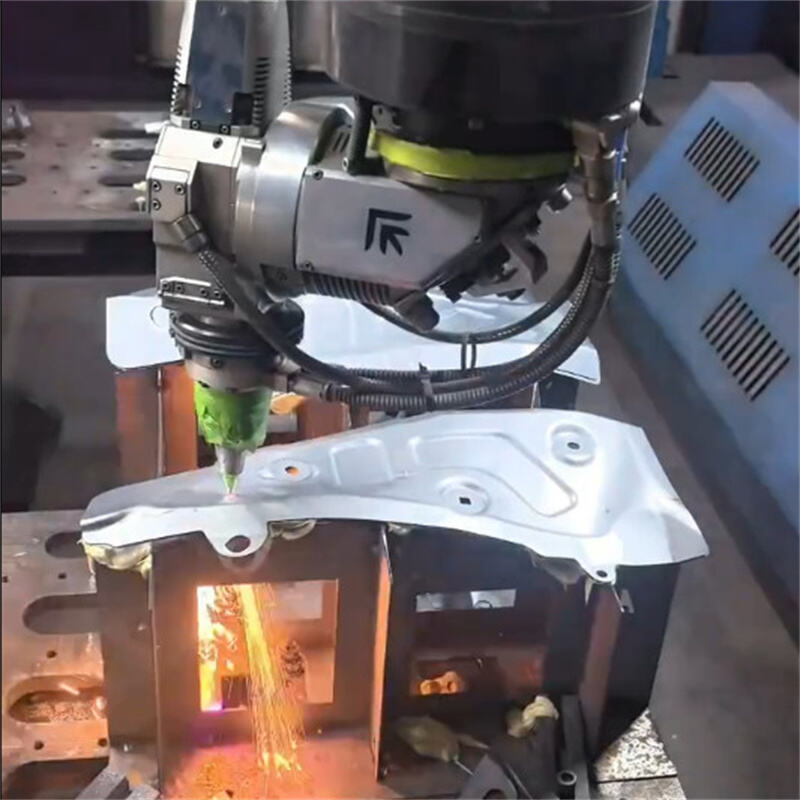

3. Welding technology: Robot welding ensures both strength and appearance

The use of automated robot welding makes the weld seams more uniform and smooth, reducing human errors. It is particularly suitable for automotive parts, frame products, load-bearing structural components, etc.

4. Complete post-processing capabilities

From powder coating to electroplating, from anodizing to wire drawing treatment, we offer a wide range of surface solutions to enhance the corrosion resistance, appearance texture and service life of our products.

5. Support secondary processing and assembly

It can be combined with nut spot welding, tapping, riveting, laser cutting, CNC precision processing and other processes to provide customers with complete assemblies, reducing supply chain links.

Automobile parts: brackets, mounting plates, structural components, metal parts for seats

Industrial equipment: frames, metal support parts, welded structural components

Electrical industry: control cabinets, chassis and cabinets, installation bases

Home appliance industry: metal casings, brackets, internal structural components

Automated equipment: connectors, transmission structural components, installation brackets

Hardware products: stamping parts, bent parts, welded parts, etc

Whether it is lightweight aluminum parts, corrosion-resistant stainless steel parts, or high-strength carbon steel structural parts, we can meet customer requirements while ensuring precision.

A: Yes, we are factory in Guangdong, China.

A:

Machining is 3-7 days for sample, 15-20 days for batch according to quantity;

Molding is 25 days for sample, 15-20 days for bulk.

A: Yes, we can, it need the sample fee, but can be refunded when place bulk order.

A: We offer flexible payment methods including bank transfer (TT), PayPal, Western Union, and Letters of Credit to facilitate secure global transactions. 30%-50% in advance, pay balance before shipping.

A: Yes, we can accommodate custom logos and packaging designs based on order quantities. Please discuss your specific needs with our sales team.

A: Yes, we support OEM/ODM customization based on your technical drawings, 2D/(PDF/CAD)3D(IGES/STEP).

Copyright © Dongguan Yuanji Technology Co., Ltd. All Rights Reserved - Privacy Policy